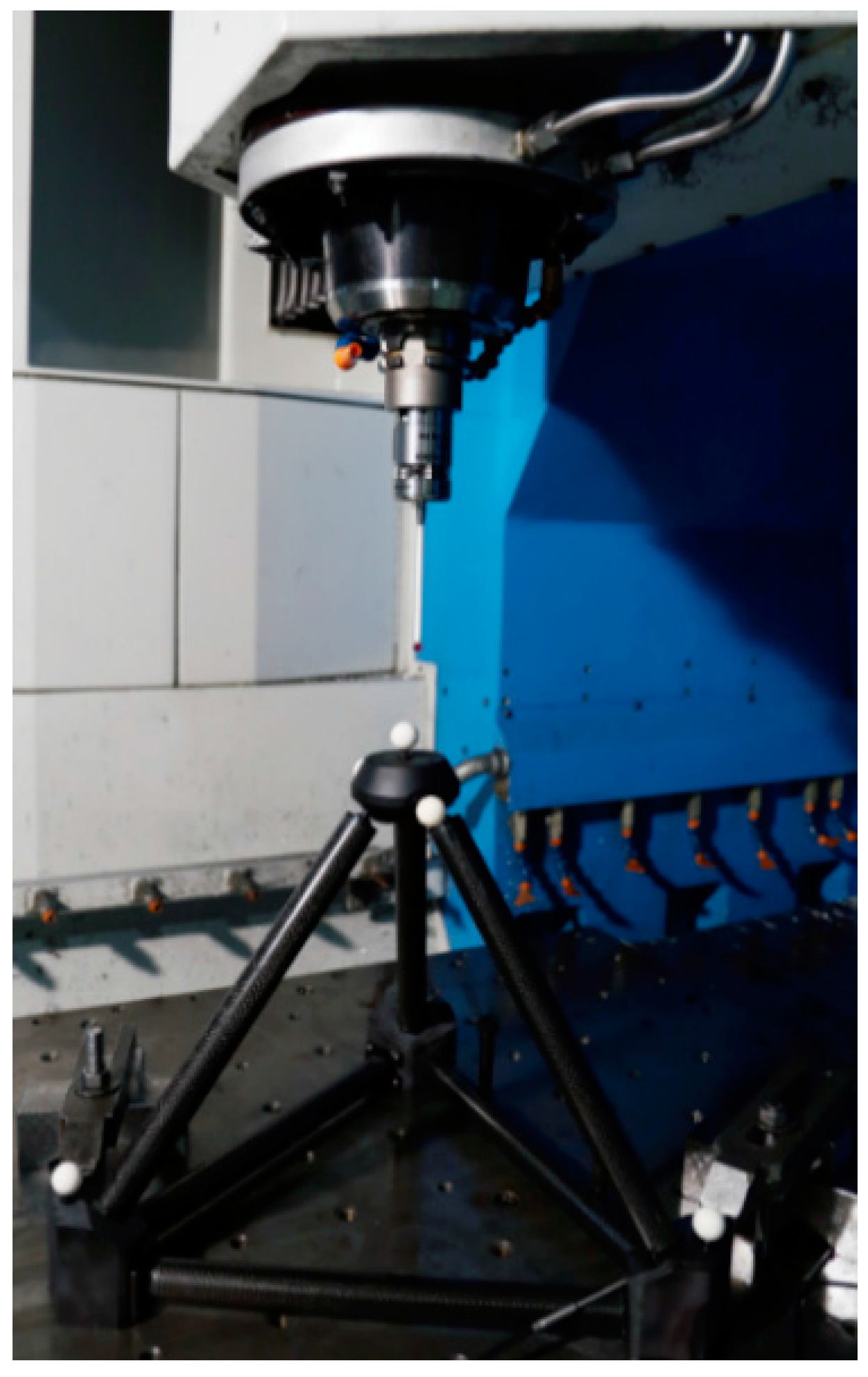

An advanced solution for precise motorcycle frame repair. Each point on the workpiece is unique to the machines coordinate system.

3d Scanning Unlocks Mountain Bike Data Metrology And

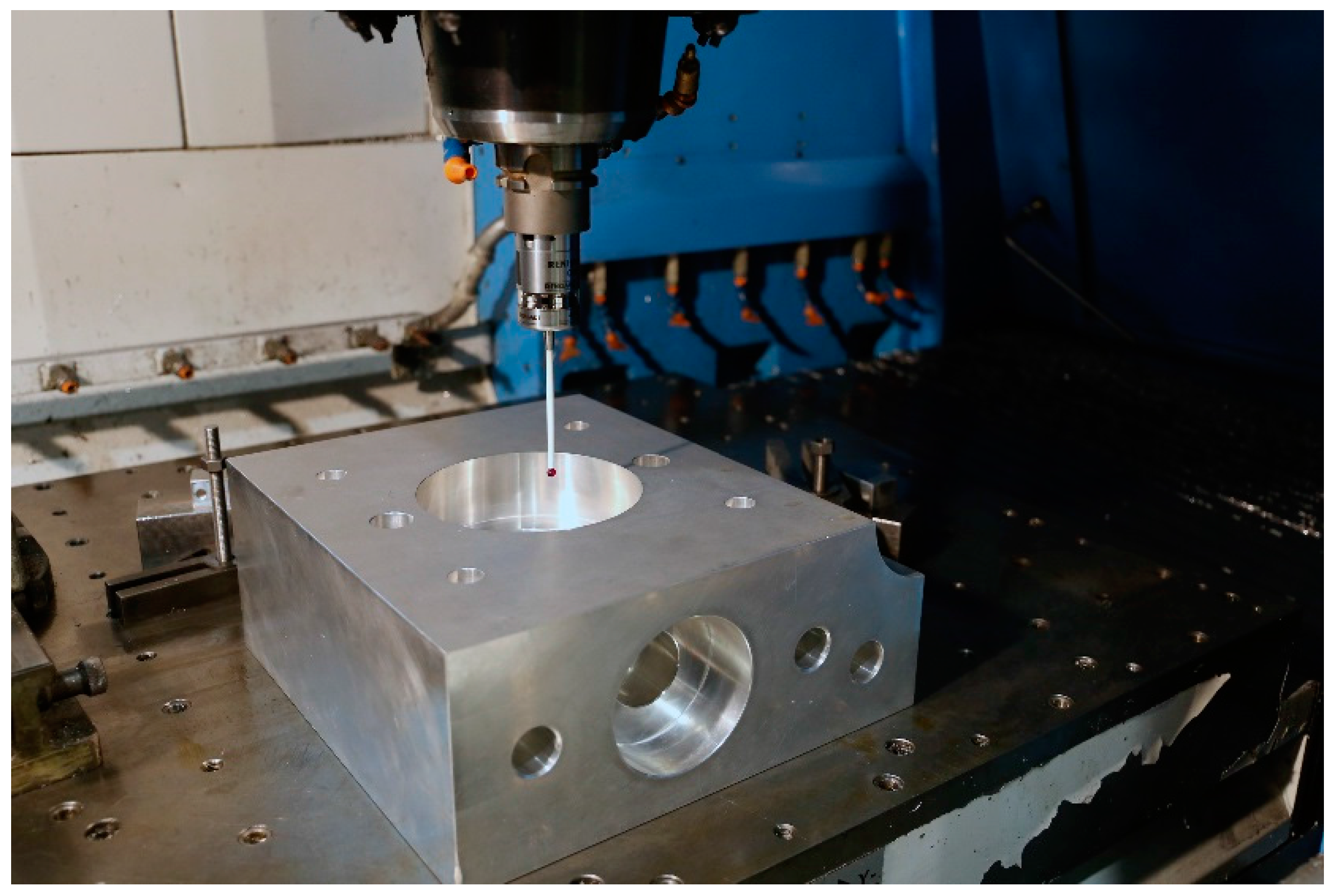

Motorcycle frame body measurement with portable cmm machine. Designed with consistency and reliability in mind the faro 3d measuring arm performs in a wide range of work environments including extreme temperatures shop floors and mobile environments. The news is that after a two year hiatus the new frame rack is up and running. Artificial turn off the power switch loosen the screw tire pressure carefully remove the hot head remove the tire complete tyre had. Faro has spent more than 30 years bringing excellence into the marketplace. Gantry cmm the multi sensor lk h horizontal arm cmms provide unequalled performance in speed accuracy and repeatability for car body and component inspection. A coordinate measuring machine cmm is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe.

Bare frame or complete bike one machine one setup. The basic distinction is between contact probes which measure workpieces by actually touching them and non contact probes which employ lasers or machine vision. Vulcanizing repair process cures the patch and inner tire lining to form a dense sealed repair job. A new twist in motorcycle frame repair. 1x tyre vulcanizing machine. Various types of probes are used in cmms including mechanical optical laser and white light.

Depending on the machine the probe position may be manually controlled by an operator or it may be computer controlled. A coordinate measuring machine is only as good as its probes. Adopting high definition daheng frame grabber ensures the image sharpness. The frame is back in frame straight. Its three axes form the machines coordinate system. Faros portfolio of portable coordinate measuring machines cmms includes measuring arms laser trackers 3d laser scanners and 3d imagers.

Inertia to ensure the long term stability of the machine. A coordinate measuring machine cmm works in much the same way as your finger when it traces map coordinates. Chief collision technology offers the most extensive line of collision repair equipment including adas calibration systems frame machines measuring tools anchoring systems welding aluminum repair and more. Instead of a finger the cmm uses a probe to measure points on a workpiece. Imported key components with rigorous normative assembling and adjustment 4 axis controls full automatic measurement being equipped with full automatic zoom body tube performs 4 axis auto measurement. As the first portable cmm arm in the market to be internationally certified to iso 10360 12 standards faro has the ideal inspection tool solution when accuracy is a must.

Measure and correct misalignments with certifiable precision. Like cmms probes come in several types. Through our wide array of products and the innovations that have come with them the 3d imaging landscape has been changed forever.